Shimadzu DUH-211S Dynamic Micro Hardness Tester

Key capabilities:

- Hardness measurement and materials characterization according to the accepted standards – ISO 14577-1 Annex A. Instrumented indentation test for hardness and materials parameters -- Part 1: Test method

- Materials characterization based on "load/ target surface"

- High-precision elastic modulus measurement

- Controlled force application, resolution – 0.196 µN

- Wide range of loads – from 0.1 to 1,961 mN

- High-precision dip of the track measurement

- Wide range of testing techniques

- Variety of indenters (Vickers and Knoop tests are also possible)

- Cyclic tests

Applications:

- Thin films (specially treated surfaces, e.g. nitride layer)

- Plastics

- Rubbers and elastomers

- Metal materials

- Fibers (ultra thin films, such as optical and carbon fibers)

- Glasses, ceramics, etc.

- Electronic parts

Shimadzu Servopulser U-type Testing Machine

Capabilities:

A wide range of strength tests – from static strength to fatigue strength – using multiple fatigue cycles. Maximum test force: dynamic force – 200 kN, static force – 240 kN. Test stroke – up to ±50 mm.

BuehlerMicromet 5103 Buehler Micro Hardness Tester

Parameters:

- Type: Digital tester with an LCD console

- Test loads: 10, 25, 50, 100, 200, 300, 500, 1000 gf

- Manual turret

- Two objectives: ´10 and ´50

- One indenter: Vickers or Knoop

- Automatic control

- Loading time: 1-30 sec.

- 50W halogen illuminator with adjustable aperture

- Manual XY sample stage

- Stage movement: 25´25mm

- Reading resolution: 0.001 mm.

МК-30 Impact Pendulum-Type Testing Machine

Specifications: МК-30 Impact Pendulum-Type Testing Machine with maximum potential energy store of 300kgf•m (~300J), 150kgf•m (~150J).

Testing capabilities: Two-point impact bend testing of metal and alloy specimens of 1-3, 5-13 and 19 types per GOST 9454-78 (Charpy test).

EMCO TEST M4C/R G3 Universal Hardness Testing Machine

Specifications: Test loads from 5 kg to 187.5 kg. Max. test piece height – 260 mm. Touch screen. Automatic hardness measurement.

Hardness measurement:

- Vickers test. A pyramidal diamond indenter is pressed against the test surface. The Vickers hardness tester should be capable of measuring both diagonals of the impression with the accuracy of up to 1 µm.

- Rockwell test. A 120° diamond indenter or a 1.588mm-diameter steel sphere is pressed against the test surface. The Rockwell tester is equipped with a special indicator that indicates the hardness value of the tested material.

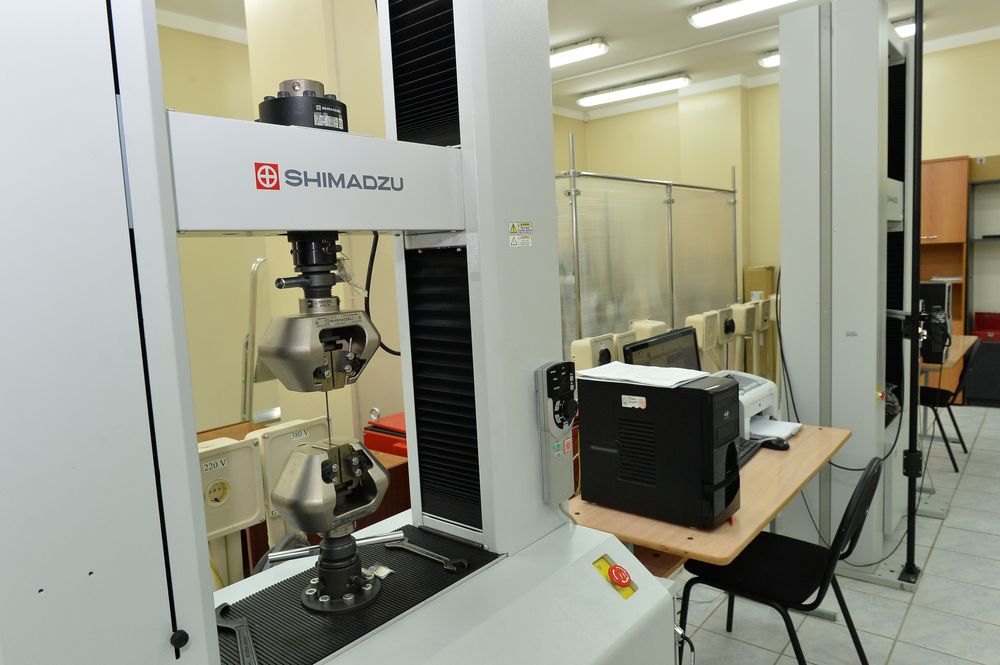

SHIMADZU AG-IC Universal Testing Machines

Specifications: Test force – 50kN, 300kN, Accuracy Class 1 acc. to ISO 7500. Speed range from 0.0005 to 500 mm/min. Max. travel during tensile test – 600 mm. TRViewX 240S video extensometer, Accuracy Class 0.5 acc. to ISO 9513, measurement range – 240 mm.

Testing capabilities:

- Tensile, compression, 3-point bend tests at room temperature.

- Tensile testing of cables and wires.

GLEEBLE 3500 Physical Simulation System

Specifications: Max. force – 100 kN. Heating and cooling rates – up to 10000 оС/sec. Max. heating temperature – 1750 оС. Displacement rates – up to 1000 mm/sec. Thermocouples are used for temperature control. Testing can be done in vacuum or protective atmosphere.

Testing capabilities:

Materials testing:

- Hot tensile/compression testing: uniaxial compression, Strain Induced Crack Opening (SICO)

- Stress curves

- Melting and solidification

- Nil strength testing

- Hot ductility testing

- Thermal cycling/heat treatment

- Dilatometry/phase transformation: heating or cooling, continuous or non-continuous, isothermal, post deformation, stress relaxation studies, creep/stress rupture

Process simulation:

- Continuous csting

- Hot rolling

- Forging

- Extrusion

- Welding (heat-affected zone studies)

- Upset butt welding

- Diffusion bonding

- Continuos annealing

- Heat treatment

- Quenching

Zeiss Axio Observer 3 Inverted Metallographic Microscope

Key features:

Binocular head with 45° inclination, video output

Nosepiece for 6 objectives: 50x, 100x, 200x, 500x, 1000x

High-resolution plan semi apochromats for brightfield, darkfield and polarized light observation modes:

- EC Epiplan-Neofluar 5x/0.13 HD M27 (WD=14.5mm)

- EC Epiplan-Neofluar 10x/0.25 HD M27 (WD=9mm)

- EC Epiplan-Neofluar 20x/0.50 HD M27 (WD=2.2mm)

- EC Epiplan-Neofluar 50x/0.8 HD M27 (WD=0.60mm)

- EC Epiplan-Neofluar 100x/0.90 HD M27 (WD=0.28mm)

Stage 250х230mm

Variety of contrasting techniques

Circular Differential Interference Contrast (C-DIC)

Reflector module darkfield ACR P&C for reflected light

Testing capabilities:

- Determination of average grain size (GOST 5639-82, GOST 21073-75, astm e1382, astm e112, din 50 601.)

- Determination of the inclusion or second-phase constituent content of metals (astm e1245.)

- Analysis of graphite microstructure in cast iron

- Graphite nodularity in cast iron

- Quality analysis of graphitic materials GOST 26132-84

- Determination of the porosity of carbon material

- Graphite content evaluation procedure for carbon materials

- Grain anisometry evaluation procedure

- Determination of banded structures in steel

- Pearlite microstructure analysis

- Pearlite colony sizing

- Determination of the sorbitic to lamellar pearlite ratio

- Metallurgical quality analysis of heat-resistant nickel alloys

- Quality analysis of two-phase titanium alloys

- Measurement of layers and coatings

- Template matching techniques

Meiji-200 Techno Inverted Metallographic Microscope with Thixomet PRO Image Analyzer

Specifications:

- New advanced Infinity Corrected Optical System, infinity tube lens: F = 200mm

- Planachromat Epi objectives: 50x, 100x, 200x, 500x,1000x

- Super Widefield High Eyepoint 10X focusable eyepiece that accepts 22mm reticules

- Ergonomic binocular heads with photo/video output

- Stage 180x245 mm

- Illuminator with 6 volt 30 watt halogen bulb

- Photo/video output at the base front end

- Photo and video documentation

Testing capabilities:

- Determination of average grain size (GOST 5639-82, GOST 21073-75, astm e1382, astm e112, din 50 601.)

- Determination of the inclusion or second-phase constituent content of metals (astm e1245.)

- Analysis of graphite microstructure in cast iron

- Graphite nodularity in cast iron

- Quality analysis of graphitic materials GOST 26132-84

- Determination of the porosity of carbon material

- Graphite content evaluation procedure for carbon materials

- Grain anisometry evaluation procedure

- Determination of banded structures in steel

- Pearlite microstructure analysis

- Pearlite colony sizing

- Determination of the sorbitic to lamellar pearlite ratio

- Metallurgical quality analysis of heat-resistant nickel alloys

- Quality analysis of two-phase titanium alloys

- Measurement of layers and coatings

- Template matching techniques

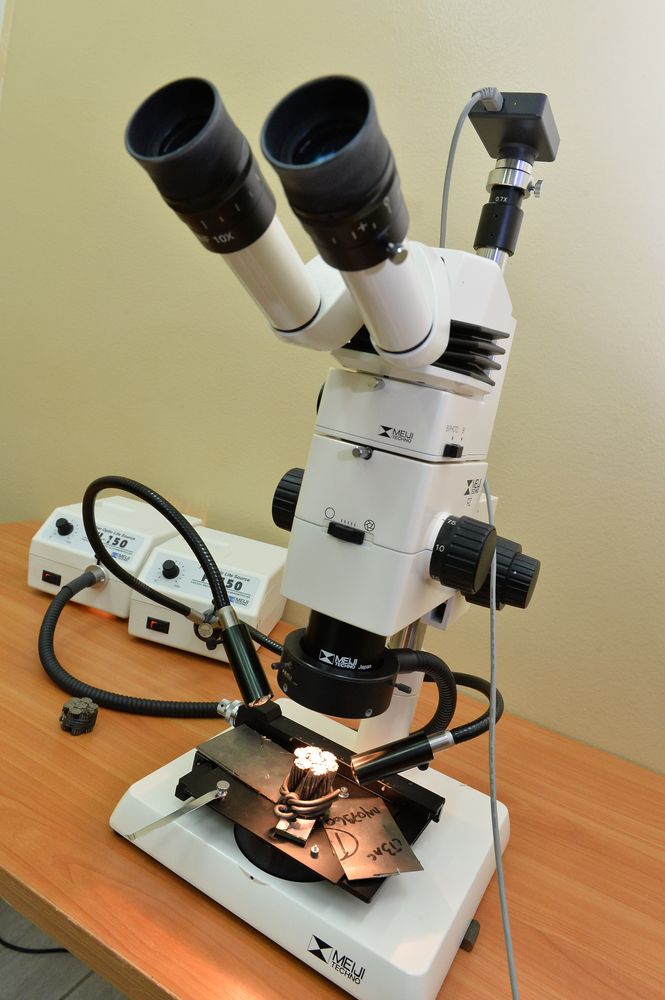

MeijiTechnoRZ-В Stereo Microscope with Thixomet PRO Image Analyzer

Specifications:

- Abbe optical scheme

- Total magnification (of a set of eyepieces and objectives) from 3.75x to 300x. ZOOM 1:10 (0.75x - 7.5x).

- Main Plan Achromat objectives: 0.5x, 0.75x, 1.0x, 1.5x, 2.0x.

- Ultra widefield objectives with diopter adjustment: 10x, 15x, 20x.

- Standard binocular head with 45° inclination; ergonomic binocular head with adjustable inclination of 10–50°.

- Photo and video documentation.

Testing capabilities: Fracture surface analysis

JSM-6490LV JEOL Scanning Electron Microscope with the following Microanalysis System: INCA Energy 450 x-МАХ 50 Premium, HKL Premium EBSD System Nordlys II 2 S Oxford Instruments Ltd

Specifications:

- Thermionic electron emission gun;

- Accelerating voltage 0.3 – 30 kV;

- Magnification from x 5 to x 300 000;

- Resolution up to 3.0 nm (at 30 kV);

- Image modes (secondary electron image): Composition, topography, shadowed;

- Computer controlled eucentric specimen stage.

Applications:

- Microstructural studies of various inorganic materials;

- Surface topography and quality phase analysis;

- Possibility to handle large specimens (height up to 45 mm, diameter up to 200 mm).

Auxiliary Equipment

- Buehler IsoMet 4000 Precision Saw

- Buehler Phoenix 4000V Sample Grinder & Polisher

- Buehler Simplimet 1000 Automatic Mounting Press